PRODUCT

11. Measuring analyzing equipment

for WPS/PQR

Welding Expert WPSSPOT

Main Features

- It allows a worker to perform precise welding upto 500 passes per one specimen and to collect data

- SMAW, GMAW, GTAW*, FCAW, SAW and TANDEM welding are available (GTAW optional)

- Current, voltage, welding speed, heat input, preheating and automatic control of interpass temperature

- Automatic production of report and output in EXCEL format

- Powered by high capacity battery (18,000mAh)

Main Purposes

- Essential equipment to nuclear relate industries, chemical plant, shipbuilding, wind power industry, etc.

- Obtaining the most reliable WPS and PQR data

- It can be used as an internal calibration reference instrument for welding machines

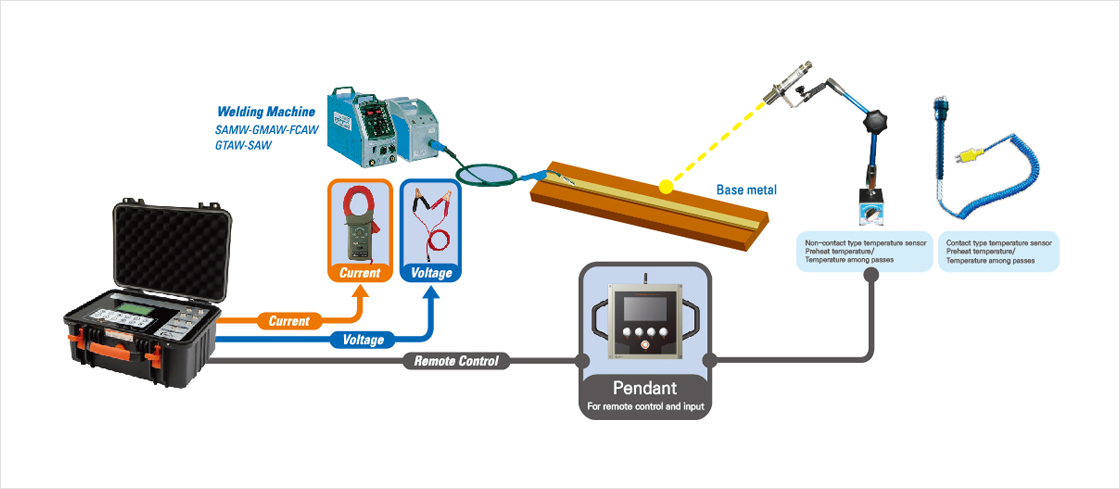

Basic Configuration of WPS

Specification S/

| Model Name | WEW-7000 |

|---|---|

| Size(mm) | 415(W)X325(D)X195(H) |

| Weight(kg) | 5.5 |

| Applicable process | SMAW, GMAW, GTAW* ,FCAW, SAW (TANDEM Available) *Optional |

| Maximum number of Pass | Sequential measurement and storage up to 500 passes each test specimen |

| Data inquiry | Data query through an exclusive LCD (main body) or data query and analysis using exclusive S/W |

| Data storage | Automatic storage in a SD Memory card |

| Measuring item | Current, voltage, welding speed, welding time, heat input, preheat temperature and inter-pass temperature |

| Product composition | Main body + Exclusive Pendant + Sensor + S/W |

S/W Main Functions

-

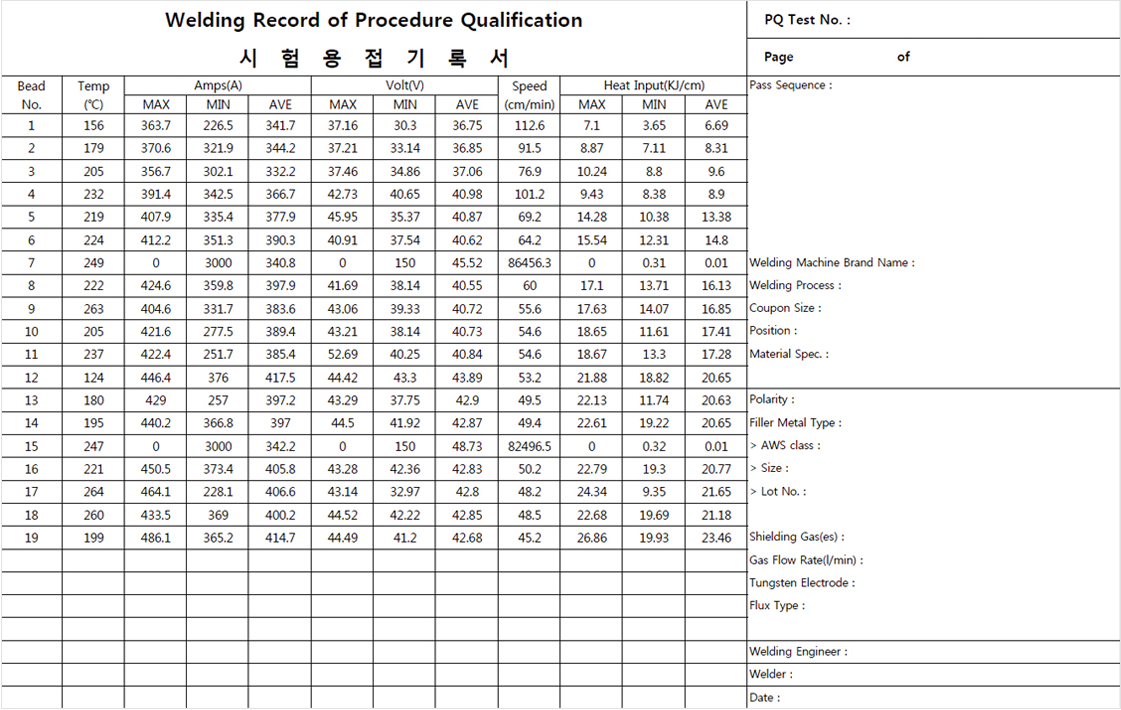

View to DB List

Bead number, inter-pass temperature, current (Max. Min and Ave) Voltage (Max. Min and Ave), welding speed and heat input (Max. Min and Ave)

-

View Ddetailed data

Indication of each bead in detailed graph, able to set the upper and lower limit and calculate its spread

Output of WPS/PQ Record

Main Clients

- Hyundai Heavy Industries, Doosan Heavy Industries, EEW Korea, Daewoo Shipbuilding & Marine Engineering, Doosan Engineering & Construction, Korea Institute of Industrial Technology, etc.

Privacy Policy

General Term

MONITECH establishes and discloses the following privacy statements to protect personal information about the information subject pursuant to the Personal Information Protection Act of Article 30, and handles the related complaints seamlessly. We will inform you about the purpose of your personal information through our privacy policy and what measures are being taken to protect personal information.

Consent to collect personal information

MONITECH established a procedure which you can click the "Accept" button or the "Do not agree" button on the contents of the MONITECH website(http://www.monitech.co.kr/), and we deem that you agreed to the collection of personal information by clicking the "I agree" button.

※ This service (site) does not collect personal information of children under the age of 14 and does not post or provide harmful information to children. The purpose of collecting personal information MONITECH'swebsitecollectsonlytheminimumpersonalinformationnecessaryfortheuseoftheserviceatthetimeofregistration.

Personal information that is processed is not used for purposes other than the following. If the purpose of use is changed, we will implement necessary measures, such as obtaining consent in accordance with the Personal Information Protection Act of Article 18.

You are required to input your desired ID, password, name, address, phone number, mobile number, e-mail, date of birth, IPIN DI (check duplicate sign-up) in order to use the services of MONITECH's homepage. However, there is no limit to the use of the service even if you do not input the selected item (such as the relationship with MONITECH).