PRODUCT

NextNDT

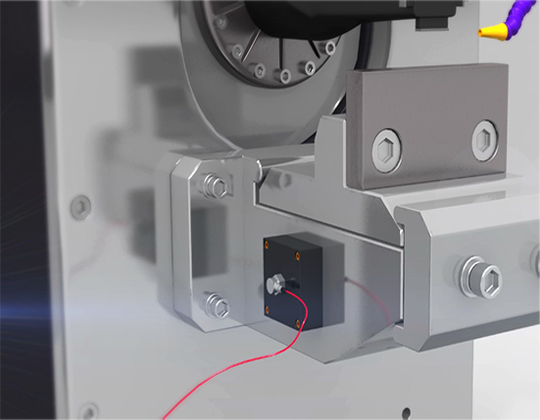

Ultrasonic non-destructive testing equipment

NextSpot 300, NextSpot 600

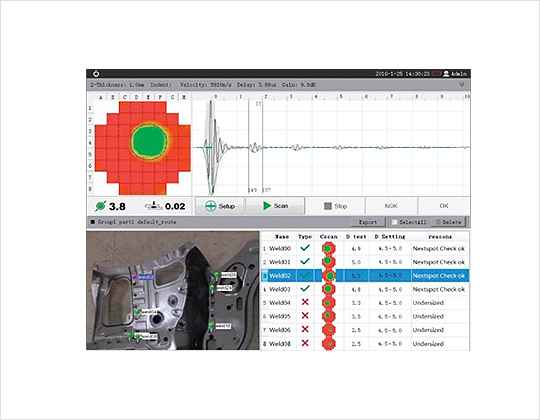

- Utilizing patented technology developed through several years of research and development in the NDT industry, the NextSpot Series automatically detects spot welding defects and generates real-time imaging quickly and accurately.

- In the increasingly competitive automotive manufacturing sector, the NextSpot Series, with its user-friendly interface and powerful features, saves valuable time and enhances productivity.

Video

Key functionsand features

- It utilizes a highly energy-efficient ARM processor and operates without a fan.

- A fully charged device can perform normal operations for 12 hours, requiring only 3 hours for a complete charge.

- It features an outstanding visual interface with a 10.4-inch full-touch screen providing XGA wide-angle view.

- Accurate measurements are ensured with 64 channels, 1MHz-25MHz bandwidth, and a 400MHz/12-bit DSP.

- It offers scanning and real-time display for spot welding, supports single-element probe testing, PA imaging testing, as well as various non-ultrasonic methods, data capture, chisel inspection, visual inspection, and more.

- The powerful, flexible, and user-friendly software is based on the Linux OS platform.

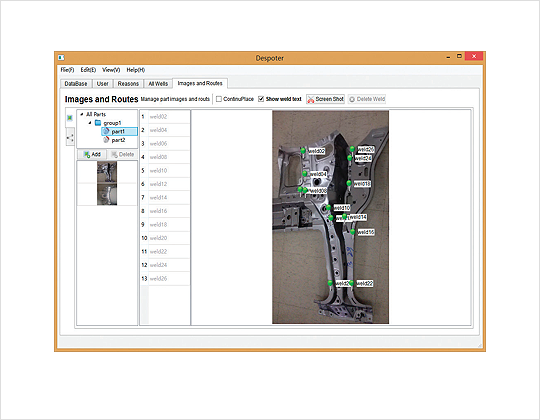

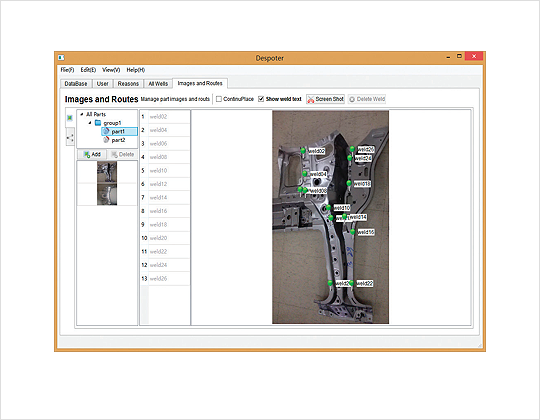

NextSpot User Interface

NextSpot User Interface NextSoft Studio (Option)

NextSoft Studio (Option)