PRODUCT

Struers

Macroscopic Inspection Equipment for Welding Joint Cross Sections

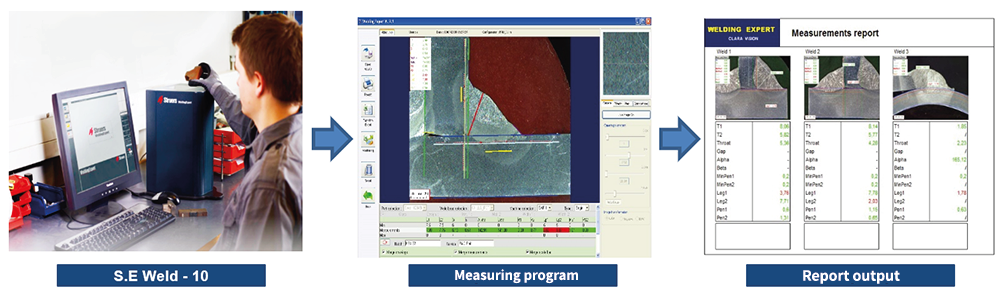

S.E Weld-5, S.E Weld-10

- Macro Cross-Section Inspection Equipment for Key Welding Components in the Automotive Parts Industry.

- Used for Macro Cross-Sectional Inspection in Welding Material Manufacturers' Research Laboratories, Universities, and Welding-related Institutions.

- A groundbreaking device specifically developed for the measurement and inspection of weld macro cross-sections.

- Provides accurate measurement and analysis of weld beads, contributing to the improvement of welding quality

Video

Key functionsand features

- Implementing Optimal Weld Bead Control → After the completion of cross-sectional etching, the specimen can generate a report within just 1 minute.

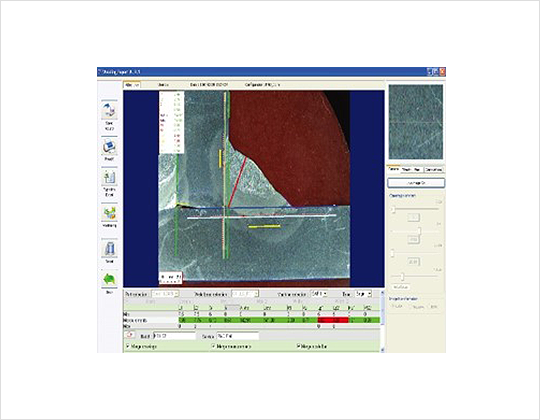

- Full PC Control without adjusting optical devices → After the initial automatic calibration, all measurements and report generation can be completed with just a few mouse clicks.

- Enables rapid and precise measurements, along with easy creation and output of professional reports

- No need for optical device adjustments, automatic calibration feature provided

- Measurement items : Weld penetration, throat thickness, leg length, base metal thickness, concave/convex angle, bead height, and other applicable measurements

- Can measure samples ranging from 0.7mm to 80mm with precision up to 0.5µm, measurement values exceeding the tolerance are indicated in red or green.