PRODUCT

VITRONIC

Real-time 3D weld bead precision inspection system

VIRO WSI

- Used globally to inspect welding and brazing joints in the production processes of hundreds of products, including chassis components, bodies, wheels, seats, exhaust systems, etc.

- Automation of weld core inspection (simultaneous rework) reduces production time and costs.

- Ensures thorough and objective inspection of produced parts according to various quality criteria, leading to significant quality improvement.

- Compatible with existing production lines with an End-to-End automation chain (from assembly to automatic rework process).

- Capable of inspecting multiple welding locations with a single inspection system.

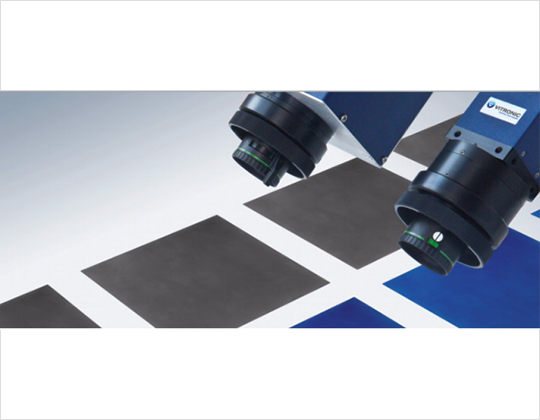

- Faster inspection than welding, records 2D and 3D images, providing optimal reliability

Video

Key functionsand features

- The use of AI/Deep Learning technology enables reliable detection of welding defects.

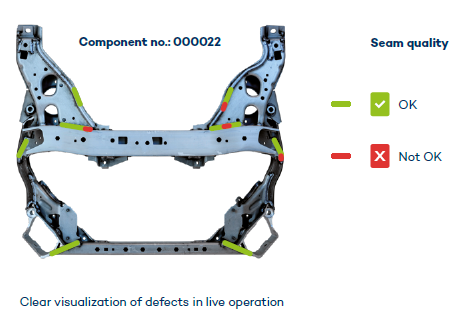

- Various defects detection based on welding methods : bead length, position, width, outer diameter, inner diameter, overwelding, undercut, porosity, spatter, etc.

- Product quality monitoring and documentation of statistics/analysis are possible.

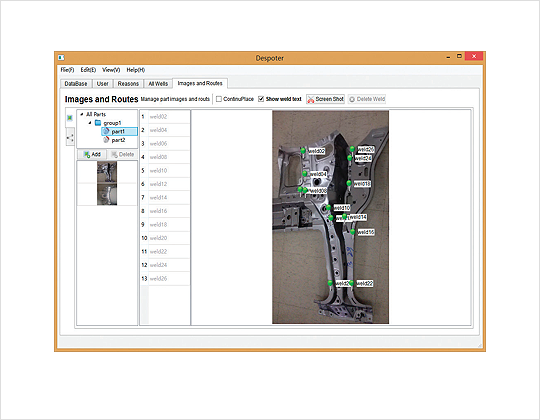

- Easy inspection program and settings (templates for different welding types, semi-automation of allowable tolerance calculation, etc.)

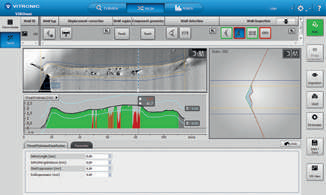

- Detailed inspection results and parameters are verified through 3D visualization.

- Inspection of flat brazing weld beads and high-reflectance materials such as aluminum is also possible.

- Automatic inspection and calculation of welding defect locations allow for manual, automatic, and robot-based rework.

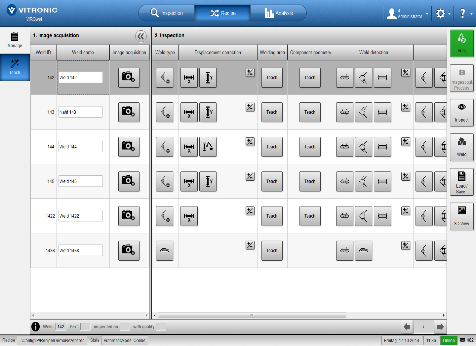

Easy program setup

Easy program setup Inspection criteria setup screen

Inspection criteria setup screen Database analysis, and statistics

Database analysis, and statistics